A natural wood finish is often desirable, when you require surface texture on the wood to maintain grip for decks for instance, or a natural wood finish look to garden furniture. Rotting of the wood will occur rapidly in unprotected timber however, so a finish is required that protects without showing.

I want my timber to have a natural wood finish; but protected from damage

It may be necessary to restore deteriorated decking or garden furniture, but at the same time maintain the natural wood finish appearance of the timber, to give that rustic look. A boat deck or decking will be too slippery if finished with Smiths CPES™ and then varnish, and a more grippy surface texture can be obtained by following the instructions below.

Normal Use of CPES protects wood, but needs UV protection

Clear Penetrating Epoxy Sealer (CPES) applied to a surface in the usual manner leaves a gloss finish. This is not a natural finish wood, rather a gloss finish. As CPES is attacked by ultraviolet in sunlight, this finish then degrades. This happens to all commercially available epoxy systems.

Protecting the wood and leaving a natural wood finish

To get a natural finish, with enhanced surface texture and grain, we follow a different procedure.

This procedure still protects the wood from rot, making it very water and of course stain resistant. Smiths CPES penetrates deeply into the surface of the timber, providing a microporous breathable surface to the timber. This means that the wood does not get damp enough for rot to begin. This further provides the protection required by wood to last outdoors. Mix and apply the Smiths CPES to the surface of the wood as normal. Apply enough coats that the wood stops absorbing more. Apply these coats over a period of a few hours typically.

A few hours after application of the CPES to saturate the wood, most of the solvents have evaporated. However the resin film on the surface has not yet cured. The resin system is a very special one, in that it cures very slowly. If you want to know more about the science behind that read here: Science behind CPES. Wiping the surface resin film with a rag soaked in our ECS dissolves and removes that film. Wiping the residue with a rag or paper towel soaked with our Epoxy Cleanup Solvent will remove the film. The epoxy resin will be scarcely cured at all, even several hours later, out of direct sunlight. The resin that has impregnated the porosity of the surface will not be dissolved in the brief time the surface is exposed to the solvent and wiped clean.

CPES is efficiently dissolved in the solvent blend that comprises Epoxy Cleanup Solvent. Mineral spirits or turpentine do not work. Acetone or MEK evaporate too rapidly to be useful in this sort of application.

How Natural is The Wood Finish After CPES Protection?

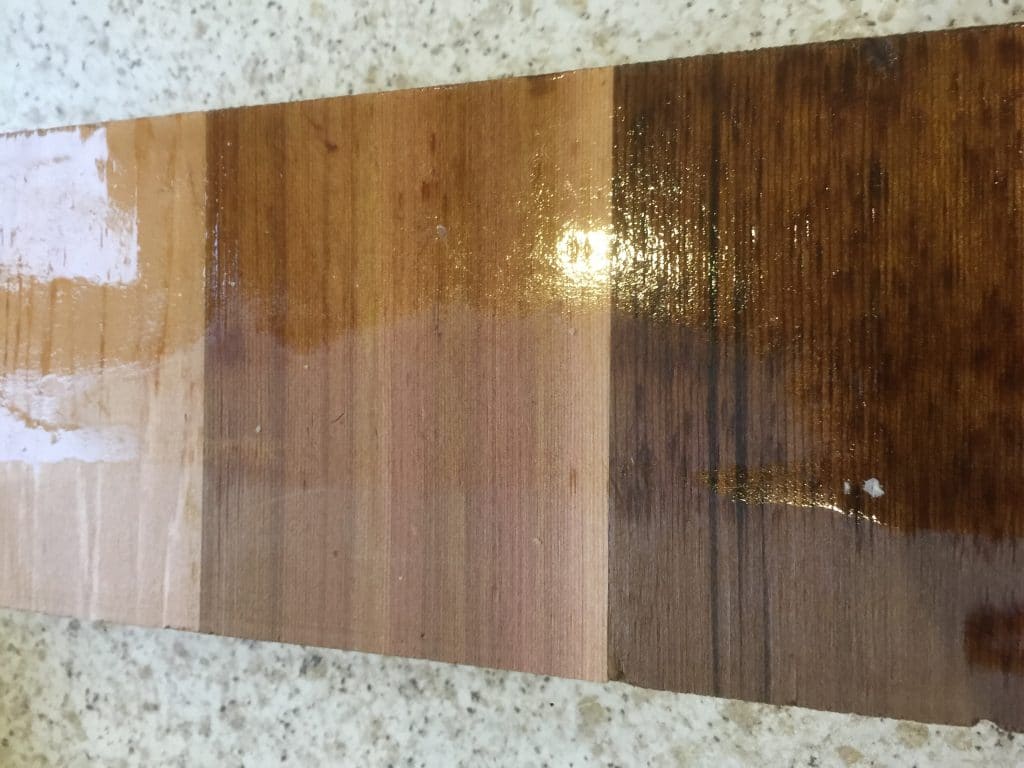

The following photographs are of a section of reclaimed red cedar. This is to be commissioned as a staircase and of course is far to soft for there to be any long term durability to the treads.

We treated two thirds of the top surface of the cedar with 4 coats of Smiths CPES, over a period of about 5 hours. This saturated the surface – leaving it with a shiny finish as expected of saturated timber. This porous timber consumed between 0.5 and 0.75 Litre / sq metre to saturate it fully.

Next we wiped a portion clean with Smiths Epoxy Clean Up Solvent to remove the shine and leave a natural finish. This is clearly seen and compared to the completely untreated timber next to it.

The areas treated are marked below.

An edge shot indicates penetration of the Smiths CPES through the cedar.

How good can this protected natural wood look?

Better than you may expect is the simple answer. The oak shaker doors below were finished, inside and out, in under two hours.

You can read more about protecting interior timber from stains and water here.

I want to stain and protect my wood, whilst keeping it with a matt natural wood finish

You may stain a few days later if required. Oil-based stains with a mineral spirits solvent system will be compatible sooner than a waterborne stain. Waterborne stains will require some additional days drying time for the wood. Normally wood is stained before the CPES and a clear finish are applied. That is because stains need to bond to the wood surface fibers, and look unnatural when applied to wood with an epoxy film on the surface. Once the wood surface has been cleaned of the epoxy film as described above, then a stain may be applied as the final finish if desired.

Copyright Steve Smith and Stephen Dakin 1993 – 2017, All rights reserved

-

Price range: £75.00 through £353.00 Select options This product has multiple variants. The options may be chosen on the product page

-

Price range: £20.00 through £52.00 Select options This product has multiple variants. The options may be chosen on the product page